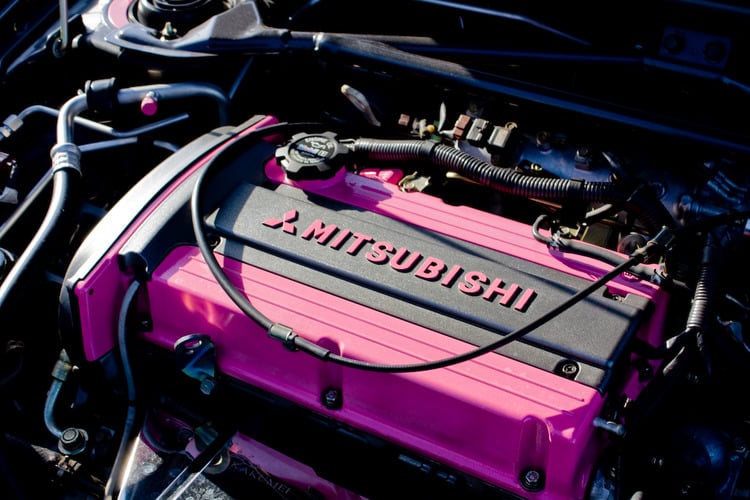

4G63T – The Best 4-Cylinder Ever?

Best known as the beating heart for nine generations of the Mitsubishi Evolution, it’s easy to see why many JDM fans believe the 4G63T is the ultimate 4-banger.

History and family of the 4G6

It all started in 1969 when Mitsubishi started a series of 4-cylinder gasoline and Diesel engines. The series had four different families; The Sirius series from which the 4G63T was later born, the Saturn series, the Astron series, and the Orion Series.

The 4G6 or the Mitsubishi Sirius was the series of the most preferred gasoline engines, mainly on the streets and especially in the World Rally Championship in the so-called “Turbo era” in the eighties.

The production of this series started in 1976 and continued till 2013 before being phased out in the US and replaced by its successor, the powerful and brand-new 4B11T. The 4G63 also underwent many improvements; for example, the later versions’ air intake and fuel injector systems were significantly improved.

This engine had three generations which powered nine generations of the legendary Mitsubishi Lancer. The 4G63 was eventually made much more efficient, and the cutting-edge technology of the Japanese needs no explanation.

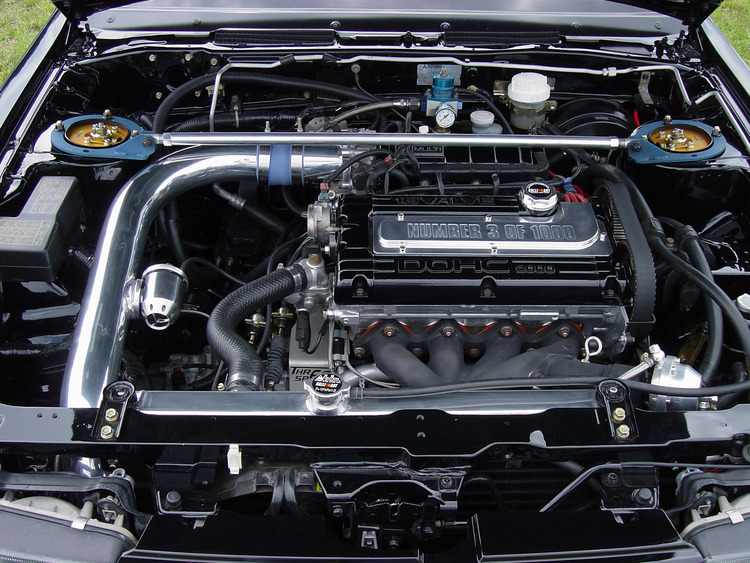

This engine is made of pure cast iron, making it heavier. Still, it gives extreme structural integrity, and the aluminum heads allow the engine to handle enormous amounts of power easily.

Sirius Series

Sirius engines use regular Mitsubishi engine codes, with the first letter (4) indicating the number of cylinders. The second (G) denotes the fuel, which is gasoline.

The third character relates to the engine family, and the fourth to the engine itself; each engine is assigned a unique number that has nothing to do with engine size. The last character (t) specifies whether or not the engine is turbocharged.

The 4G61

This was the first in the long line of power plants that powered the World rally Championship for a long time. This engine displaces 1,595cc (1.6L) with a bore of 82.3mm x 75mm.

This engine was a DOHC 16-valve and was fuelled by either an ECFI (electronic controlled fuel injection) or an MPFI (Multi-point fuel injection). Other Sirius motors had balance shafts, while the 4G1 did not have a balance shaft. This engine produced 105 HP at 6,100 rm.

The 4G62

The 4G2 was a larger engine that displaced 1,795 ccs (1.8L). It has a bore and stroke of 80.6 mm × 88 mm. The 4G62 was a SOHC 8-valve engine designed for longitudinal rear-wheel drive and all-wheel drive use.

This engine was available in either carburetor form, MPFI or ECI. Another version of this engine was the turbo charge 4G62T.

The 4G63/G63B

The 4G63 was the most preferred in this series due to its robust engine structure and also due to its ability to be heavily modified for vast amounts of pure power.

This engine also had its more famous 4G63T, the turbocharged version. This engine displaces 1,997cc (2.0L). The bore stroke is 85 mm × 88 mm, this engine was produced in both SOHC and DOHC, and both were available in either naturally aspirated or turbocharged versions.

The Mitsubishi 4G63T was first introduced in the 1980s. The engine’s 1G and 2G models were used in various vehicles, including the Mitsubishi Galant VR-4, the Eagle Talon TSi, and the Plymouth Laser RS Turbo.

Diamond Star Motors (DSM), a joint venture between Chrysler and Mitsubishi, played a significant role in developing the 4G63T engine, as it was used in many cars produced by DSM.

The 4G63T engine was unique because it was one of the first mass-produced turbocharged four-cylinder engines, allowing it to produce higher power levels than many of its contemporaries. Over the years, the engine was continually refined and improved.

From 1G to 2G, changes include:

- Oil sprayers were added to the connecting rods to help cool the piston crowns and reduce friction

- Lighter pistons and rods were used to reduce engine weight and improve the revving capability

- Seven-bolt attachment on the cylinder head was used to improve head gasket sealing and boost pressure

- Power increased from 200 horsepower in the 1G model to around 300 hp in the 2G model.

- Additional components, such as a larger turbocharger, a more efficient intercooler, and a stronger crankshaft, were added.

The 4G63t’s tough bottom end has features that have become increasingly rare because of carefully optimized production engines, increasing emissions regulations, and drastic weight-saving programs. Of course, like any motor, the 4G63t has its weaknesses.

Some motors have thrust bearing problems with no clear solution, and the balance shafts are not optimal for performance use. In addition, the engine’s smallish 2-liter displacement is an obstacle to immense streetable power. The stock pistons and rods are strong but only production parts.

The 4G64

The 4G64 was the largest variant in the Sirius gasoline series, with a displacement of 2,351 ccs (2.4L). It was available in 8-valve SOHC but was later available in 16-valve SOHC. It used Multi-Point Fuel Injection (MPFI) and had a bore and stroke of 86.5 mm × 100 mm.

4G63T/4G63 Specs

The 4G63 is also popularly called the “2JZ” of the 4-cylinder world, although the 2JZ came in the 90s while the 4G63 came in the early 70s.

The robust quality of cast iron and heavy-duty pistons generated enormous torque, and this engine was the most preferred in the world rally championship pretty much explains why it can easily handle a whopping 1000 hp.

It also was integrated with advanced MIVEC technology, which significantly increased the airflow and exhaust of the 4G63T. The 4G63 also used a 13KG crankshaft, a timing belt, and a balance shaft, which helped it control high engine vibrations.

This engine was the most iconic on the Mitsubishi Lancer Evo. This engine also has a tuning potential of 1000 hp, which we’ll discuss later.

Cons of 4G63/4G63T

There is no doubt that this engine is an excellent choice for 4-cylinder petrolheads even today, but there are some common problems with the 4G63, which, if not taken seriously, can wreck your engine.

4G63T balance shaft bearing and timing belt failure

This is one of the most common 4G63 users face. Due to the old design and age, this engine faces a critical problem. The timing belt failure. It uses belt-driven dual balancing shafts with weights that spin at twice the speed of the powerplant to counteract the vibrations.

Now constant wear and tear due to piston strokes and a lot of power being produced alongside constant friction often cause the bearings to fail, which can cause the timing belt to snap.

If that happens, then you will have to buy a brand-new engine because it will wreck the engine from the inside. To avoid it, experts suggest using high-quality engine oil and NEVER skipping routine oil changes. This helps the bearings operate efficiently.

Also, using a Kevlar belt instead of the stock belt is a good option. Most experts suggest entirely deleting the balance shaft and installing an aftermarket kit. This will increase engine vibrations, but it’s better to tolerate some vibrations instead of complete engine failure on a heavily built engine.

The lifter failure

This is a common problem and can be easily identified with a constantly ticking annoying sound from the engine. This often happens because of poor oil pressure below the throttle body.

This causes the intake manifold to reduce efficiency as the lifters do not open and stick, so the airflow is affected, affecting engine power. A common fix is to use 3G lifters and lubricate them well.

The Crankwalk problem

The crank walk problem is common in the 7-bolt version of the 4G63T, mainly because it had weaker journals. “Journals” are the cylindrical part of the crankshaft, which is also the central axis of rotation.

Because of the weaker journals, wear is quite predominant at high engine RPM. When excessive wear occurs, i.e., more than standard tolerances, the crank will start to move and vibrate when it’s rotating.

You can expect what happens next - when the crank moves, all engine internals move, and within a few seconds, you have a blown engine that is unrepairable.

Maintenance

If you wish to customize your Mitsubishi turbo, take the time to catch up on missed maintenance. Regular maintenance includes oil and coolant changes; see the paragraph above for what happens if one is neglected.

Mitsubishi advises changing the timing belt every 60,000 miles, and this is not an optional repair. An interference engine with a damaged timing belt will have bent valves. The balance shaft belt is equally crucial; a broken belt is the root cause of most timing belt failures.

Because of the engine’s layout, several minor parts, such as the crank and cam seals and timing belt tensioner, need to be replaced simultaneously with the timing belt.

Every 60,000 miles, use only genuine Mitsubishi timing belts. Because of their higher heat resistance and quality control, Robert Garcia suggests only utilizing OEM timing belts. Although aftermarket belts are OK, the price difference is modest enough that purchasing an OEM component is inexpensive insurance.

Replace the water pump every second timing belt replacement (every 120,000 miles), as it is located below the timing belt and often wears out after 100,000 miles. If the timing belt fails, you’ll have to pull it again, so replace it as a precaution.

At 120,000 miles, every second belt replacement should involve the repair of the idler bearings, tensioner, water pump, and the small hoses that deliver cooling water to the turbo. It’s not technically maintenance, but after changing the timing belt, you should also check the ignition timing. Check and reset the idling and other EFI settings as well.

Even if no signs of wear are present, the timing belt idler bearings should be replaced every 120,000 miles. Replace the water pump every second timing belt replacement (every 120,000 miles), as it is located below the timing belt and often wears out after 100,000 miles. If the timing belt fails, you’ll have to pull it again, so replace it as a precaution.

At 120,000 miles, every second belt replacement should involve the repair of the idler bearings, tensioner, water pump, and the small hoses that deliver cooling water to the turbo.

It’s not technically maintenance, but after changing the timing belt, you should also check the ignition timing. Check and reset the idling and other EFI settings as well. Even if there is no evidence of wear or roughness, the timing belt idler bearings should be changed every 120,000 miles.

Always utilize OEM Mitsubishi components for the same reason as the timing belt. You may find them for a few dollars more than aftermarket if you shop well. The hydraulic tensioner on the 4G63t engines is dependable.

It, too, should be changed after 120,000 miles. A faulty tensioner will cause the belt to get slack and skip, causing valves, valve guides, cam followers, and even camshafts to be destroyed.

The Best Part: Upgrades

The first thing most enthusiasts do when they get home with their new car is to drop the exhaust system and install an aftermarket one. This isn’t a bad idea once the engine is tuned up and running on high-octane fuel. The right DSM exhaust will pick up more than a few horsepower, and it can improve the sound of your engine.

The 1g DSM has a decently sized TD05-14b turbo and will produce good power without overheating the air. The 2g, on the other hand, has a tiny little Garrett T25 turbo that isn’t much use above stock boost levels. An additional 2-3 psi is all that can be expected from the T25 turbo, also known as the “T-too small” for its diminutive size.

The TDOSh-16G turbos installed on the various Evos, on the other hand, can easily squeeze out another 5 or even 10 psi without breaking a sweat. All 4G63t variants can handle 2-3 psi more boost from the stock turbo without a problem.

There is also enough headroom in all three engine management systems to properly fuel a few more PSI of boost and the resulting airflow. It should be evident that you need to have an accurate boost gauge before you start playing with boost tuning. Start small and test your changes slowly.

Before cranking up the boost, ensure you’re getting the expected stock boost out of your car. Test it in high gear, like fourth or fifth, to give the turbo enough time to build full boost before the engine revs increase too far.

Manual transmission 1g owners should see between 8 and 12 psi on the stock turbo and intake system, while 2g owners should see 10 to 15 psi. The Evo is a different beast; stock boost has a peak of around 19 psi that drops to around 16 psi by redline.

The ECU does not entirely control the 1g and 2g boost control systems. The ECU can only reduce the boost, not increase it. Removing the restrictor increases the target boost, as does add an aftermarket boost controller.

The second thing to remember is that the 1g and 2g DSMs have an upper limit to boost in the form of the factory “fuel cut,” which kicks in if the stock ECU senses more than a pre-set amount of airflow into the engine. The fuel cut operates at around 18 psi depending on model, year, turbo, and air temperature. The only way to remove the fuel cut is with engine management modifications (see

If you’ve got a chippable DSM ECU, a simple reprogrammed chip, and some electronics experience, it’s not hard to add a couple of horsepower to your engine. An off-the-shelf tuned ECU chip will provide some benefit but not as much as a custom-tuned program.

On a pure “dollars per horsepower” scale, a turbo-timer ranks pretty close to the bottom. You won’t make any more power, but it’s easy to install. Plug-and-play harnesses are available for DSMs and Evos, so it’s not a bad installation for practicing your electronics skills. A turbo timer keeps the oil and water flowing to the turbo as the turbine blades spin down.

An engine’s accessories, including the A/C com-pressor, water pump, alternator, and steering pump, absorb engine power as the accessory belt system drives them. Reducing the diameter of the crankshaft’s drive pulley reduces the speed at which these accessories are driven, reducing the power demands they make on the engine.

So-called underdrive pulleys do just that. The smaller, usually aluminum pulley also helps reduce the engine’s rotating mass. Other pulleys on the market are lightweight aluminum, like underdrive pulleys, but they are designed to drive the accessories at stock speeds.

These pulleys may have some cumulative effect on the engine’s rotating mass, the same as an underdrive pulley.

Conclusion

So, is this the best gasoline 4-cylinder? The answer to this question is not simple. It is true that completely stock, this powerplant is super reliable because of its build quality of cast iron and easily crosses the 250,000-mile mark with mild maintenance.

However, this engine is more popular as a tuner engine, and there is less appetite for a stock 4G63. Even today, this engine is still in production by Chinese producers. This engine was ahead of the comparatively newer 2JZ-GTE.

There is something special in the 4G63, its rich history, its high tuning capacity to the extreme power and how it was the legacy of the world rally championship, and how beautifully this power plant was built with a cast iron engine block, forged steel crankshaft, and aluminum piston heads. The 4G63 is truly the undefeated 2JZ of the 4-cylinder world.