What Is A Stroker Engine?

Want to increase your engine’s displacement? Then you will need a stroker kit. What is a stroker kit? Let’s find out!

You can click on a particular section within this article, otherwise, scroll down as we help you decide whether a stroker is best for your needs.

- The Basics – What is a Stroker?

- The Basics – Fitting a stroker Kit

- How does a stroker lead to increased power?

- Pros of a stroker engine

- Cons of a stroker engine

- Torque vs Horsepower

- Destroking an engine

- Conclusion - Does a stroker suit your needs?

Introduction

We’ve all heard it, lots. “There’s no replacement for displacement”, but what exactly are the best ways to increase the displacement in your current engine? We’re going to explain everything you need to know in our ‘What is a stroker engine?’ guide.

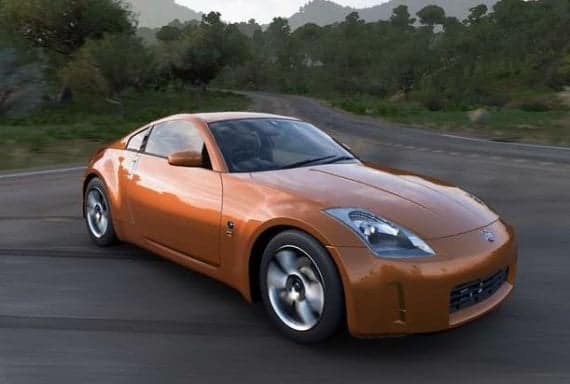

There’s no secret that we love just about anything that provides big power gains here at Drifted, and stroker kits are undoubtedly one of the most popular and affordable methods.

With the power figures being put down in drifting continuously climbing, a stroker kit should definitely be a consideration if you’re looking to join the big-power game.

As you’re probably aware, stroker engines are far from a new idea. Engine builders have been increasing stroke since the beginning of internal combustion more than a century ago.

However, as we fast forward to the present day, most serious competition drift engines are now maximizing the potential that stroker kits have to offer. Whether they’re running the commonly stroked V8, less common 2JZ or even the SR20 (SR22.)

Stroker kits are one of the most convenient ways to improve the internal power of your engine, and for those of you that aren’t interested in heading down the forced induction route for whatever reason, it’s certainly a worthwhile option.

Previously, the most popular way to stroke an engine was to swap out a crankshaft from a different engine which already had a larger stroke, but these days there is a huge range of availability with off-the-shelf kits. On the market to make life easier, and offer more variety.

You no longer need to worry about the time, costs and efforts involved with swapping out your perfectly decent engine if you’re looking for increased displacement. By increasing the stroke of your current motor, you can enjoy having far more torque hidden on the internals your ultimate sleeper package!

Huge changes in the market in recent years have seen modern machining and imported parts such as forged cranks becoming more competitively priced than ever. What would’ve taken a huge amount of work a decade ago, now just takes a fraction of the time thanks to modern technology.

With convenient mass-production comes cheaper prices, and this has made stroker kits affordable to the masses, even becoming a serious temptation for every-day fast road car owners.

So, if you’re looking to increase your engines displacement, providing increased torque as well as pushing your acceleration curve in the right direction, an ideal choice is to increase your displacement with a stroker.

We’re going to explain everything you need to know when it comes to deciding whether a stroker is going to be the ideal choice for your build in this guide.

The Basics – What is a Stroker?

A stroker increases the internal engine stroke, which is the distance covered by the piston inside the cylinder bore.

With the increased distance covered by the piston, this enforces faster rotation of the crankshaft. This then provides increased torque, therefore putting the power to the wheels to improve acceleration of the vehicle.

Check out this video as the experts at Lincoln Tech provides an in-depth explanation for everything you need to know when it comes to the basics:

Torque is extremely important when it comes to low-end power which is where larger displacement engines will undoubtedly have the upper hand.

Where shorter strokes would allow the engine to rev higher and faster (destroking), generating more horsepower, an increased stroke would increase the torque. Torque is essentially the force which will move your vehicle forwards faster.

The more torque you have, the quicker you’ll be able to accelerate. This is why torque has always seen such huge popularity in the drag racing scene where off-the-line speed is essential.

One of the best things about stroker engines is that you’re essentially provided with a superior engine within your existing package. Stealthy, unsuspecting sleepers are awesome and this additional power is tucked away inside the motor – so no-one will suspect a thing! (Well, provided you can keep quiet about it!)

The Basics – Fitting a stroker kit

Since we now know that a stroker will increase your engine displacement by providing additional length to the stroke of the piston. A stroker kit will be compiled of engine components which have been uprated from OEM specifications to achieve the required stroke increase.

This will allow the piston to travel further inside the cylinder bore due to the use of a different crankshaft. The length of the journals along the crankshaft will be adjusted by the specified distance depending on the kit chosen.

If you decide to opt away from a kit and source the parts separately then you’ll need to ensure you get the correct parts. With the wrong parts or incorrect spacing, the piston is likely to hit the cylinder head, which will inevitably end in engine failure.

Firstly, a costly, or time-consuming option of doing it without a kit is to increase the height of the block deck or the cylinder cavity. If this choice is best for you, we would recommend attempting to purchase a specific aftermarket block deck which has been designed for the use of stroker kits. CNC machining your own block is likely to be far more hassle and more expensive.

Alternatively, you can shorten the connecting rod itself, or adjust the piston pin higher up the connecting rod. This would prevent the need for the complicated cylinder head or wall machining to allow for the increased stroke.

We would personally opt for a tried and tested off-the-shelf kit. As an example, a popular engine in drifting would be the SR20, and Tomei have created their own stroker kit which turns your 2.0L SR20 into a beastly 2.2L SR22.

SR20 Stroker Kit

Within this kit, you’ll get the following:

Forged Pistons:

Forged Crankshaft:

Forged Rods:

Description

“Tomei Stroker Kits will increase the displacement at safe levels without compromising the block. By utilizing forged pistons, forged full-counter crankshaft, and forged H-beam rods, the stroker kit is filled with all the best parts to greatly improve the bottom end.“

“Depending on the bore size you go with, the displacement will increase proportionally. The bigger the bore size, the higher the displacement.“

“Each Tomei stroker kit is meticulously crafted, weighed, balanced, and designed to provide the optimal ratio between torque and horsepower, resulting in a more neutral and balanced acceleration.“

This Tomei kit and the related parts are designed for use on engines that will be outputting 1,000 HP at over 10,000 RPM. Pretty insane capabilities for an SR, right?!

We would much prefer to go with a setup like this which has had proper tried and tested research development methods carried out to ensure the best results.

Take a look around this 1000hp 2.2L 1000hp SR22 S15 to see what a stroker kit (and a heap of other supporting mods) can help you achieve from the humble SR20!

2JZ Stroker Kit

If you’re looking to get the most out of your 2JZ, a stroker will be perfect for your needs. Often used by the best drifters in the world, such as Daigo Saito, this kit will give you a whopping 3.4L displacement to play with.

The BC stroker kit for the Toyota 2JZGTE engine platform is used by the top teams in Sport Compact Drag Racing and Drift. Incorporates a 86mm, 94mm or 96mm stroke, steel billet crank, BC 4340 Pro Series connecting rods rated to 1600+ horsepower. Depending on bore size that you decide, the BC kit will take you up to a 3.4L with 87mm bore. As usual, each BC kit features custom CP aluminum forged pistons, 9310 alloy wrist pins and complete ring pack. Built for high horsepower and torque. Stroker kits also available with lightweight crank option (-8 lbs) and Carrillo rod option.

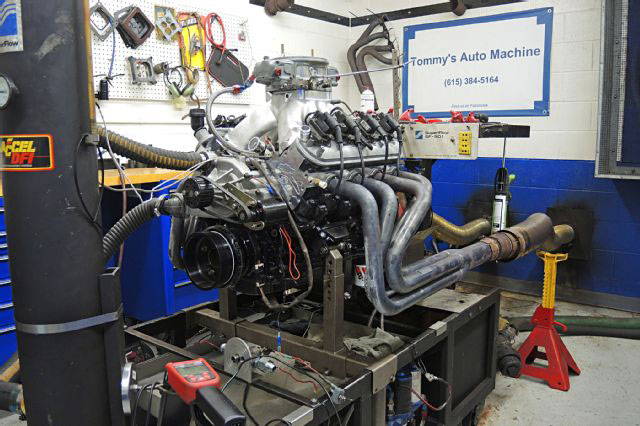

Crankshafts

BC crankshafts are made from the finest, aerospace grade 4340 steel billet material. CNC machined on state of the art, 5 axis Mazak Integrex 300-IV CNC machines to exacting tolerances (.0001″). Every crankshaft features large radius journals that add rigidity for high horsepower, high boost, high rpm applications. Gun drilled, CNC ground oil holes feature a smooth surface for extra oiling, tear dropped for added oil scoop, cross drilled for priority main feeding to the rods and micro polished to a mirror finish for optimum bearing lubricity. All cranks are stress relieved, shot peened, magna flux inspected and nitrided (multi step heat treatment) for ultimate performance. Fully profiled counterweights are designed for reduced windage through the crankcase creating less oil resistance for better rpm potential.

Connecting Rods

BC connecting rods are CNC machined from aerospace grade 4340 steel billet, available in your choice of the European influenced H beam or the traditional I beam design (certain applications). All rods feature a deep, double ribbed cap that keeps the big end housing bore true at extended rpm and ensures uniform bearing crush, delivering proper clearances for superior oil supply and maximum load carrying capacity. H Beam rods feature a deep radial groove pin bushing and oil holes at 5 and 7 o’clock (the beam acts as a trough), bringing critical lubrication to the critical wrist pin area. I Beam rods feature an oil hole at the 12 o’clock position that keep the pin end bore true at high boost. Available in your choice of ARP2000 fasteners (rated to 210,000 psi) or the ultimate faster, ARP’s Custom Age 625+ (rated to 280,000 psi).

Pistons

Choose from the top piston brands available… CP or JE… in any desired bore size and compression ratio. Both brands make their custom BC stroker pistons from 2618 T6 high tensile strength forged aluminum forgings. These forgings are computer designed for strength and minimum weight. Each piston dia is CNC machined to assure optimal accuracy and superior grain flow in the forging process. 3D modeling software and rigorous Finite Element Analysis ensure that your pistons are manufactured to the strongest and lightest part possible for your application. Your custom pistons feature tighter clearances, less noise, better ring seal and overall better durability. Standard features include pin fit, carbon steel wrist pins and spiral locks or rail supports depending on application. Added features include upgraded 9310 alloy wrist pins for reduced flex, lateral gas ports to assist in ring seal, skirt and top coatings and lightweight design.

How Does a stroker lead to increased power?

When you increase the stroke length inside your engine, you’re squeezing more volume into the same combustion chamber. This, in turn, provides an increase in compression.

From this increase in stroke and compression also comes an increase in cylinder volume, which therefore means more air and fuel to the engine. Therefore, providing more power.

Larger displacement and leverage provides creates additional torque for the engine. Thankfully, it’s not always necessary to swap out your current engine with a larger one, as a stroker kit will be able to use it to its full potential.

Since displacement is a combination of bore and stroke, as you increase the stroke, you’ll be able to squeeze that extra power out, allowing you to create the ultimate sleeper!

Pros of a stroker engine

The most useful part of a stroker engine is the additional displacement which is gained, and the benefits that come with it.

This, in turn, then provides more torque due to the engines new-found ability to ingest and burn more fuel than it was capable of with its OEM factory specifications.

As well as an increase in torque, you’ll also gain additional horsepower due to the extra stroke being carried out by the engine. An all-around power increase is always a winner!

Additional pros of a stroker engine are that the chances are your stroker kit is most likely going to provide you with stronger internal components, which will undoubtedly help you further down the line when if you decide to push your engine even further.

Once you’ve fitted a stroker, chances are you’re not going to need to downshift so much due to your new-found low-rev torque gains.

Cons of a stroker engine

Manufacturers typically put years of research and development into the engine which your car came with fitted from the factory.

When it comes to modifying, especially engine internals, there’s always an element of increased risk that something could potentially go wrong, most likely due to user error.

Most stroker kits on the market have now been used for hundreds of thousands of miles, but if they’re installed incorrectly, you can count on it being a costly mistake sooner rather than later.

Assuming you’ve got a good engine builder to carry out the work, chances are you’re going to be fine, but there are still some small downsides to stroking.

With the piston now having more work to do within the cylinder, yet doing so in the same amount of time, it could cause increased stress on the pistons and crankshaft in the long-run. However, forged internals are extremely robust, so assuming you buy a good kit, this is unlikely to be an issue.

Another downside is the inevitable cost. As with anything which provides significant gains in the automotive world, you’re most likely going to have to set aside a decent budget, especially if you’re looking for a highly regarded company to carry out the work.

Stroking can affect the engines ability to perform to its full potential in the upper RPM range, but this is usually less relevant due to the low-down torque gains which have been achieved.

If this is the case, drivers which are likely to frequently use the engine in the upper rev-range may well find it more beneficial to de-stroke and increase the bore size instead. This will, of course, provide less low-down torque, but more high-end power.

Torque vs Horsepower

This is one of the never-ending debates of tuners worldwide, and it all depends what you’re using your power for.

For a thorough explanation on the subject, we highly recommend checking out this video from Engineering Explained:

Torque is great for drag racing, where most drivers are likely to prefer horsepower for canyon runs and drifting.

There’s no doubt that a stroker engine is more aimed towards those looking for optimum torque gains, but how exactly do the two compare?

We’ve all heard of people bragging about how much horsepower their car has, but torque rarely gets anywhere near as much attention, especially in drifting.

This great quote from Judson Massingill from the School of Automotive Machinists explains it in an interesting way: “Want to run faster? It’s all about horsepower! But if you have more torque, you’ll have more horsepower!”

Think of horsepower as making you go faster, but torque being the thrust which throws the car from 0-60 and pushes you back into your seat.

Destroking an engine

So now that we understand stroking an engine, you’re probably wondering what destroking is?

Destroking is typically done by replacing the crankshaft to shorten your stroke, rather than lengthen it as you would with a stroker. When fitting a smaller crank, you have a smaller diameter and the pistons move up and down over less surface area, therefore increasing the revolutions per minute (RPM.)

You may think destroking sounds a bit crazy after convincing yourself that stroking is the way forward, but there are some seriously impressive builds out there. Check out this 1,113HP destroked LS build over on SuperChevy.

Conclusion - Does a stroker suit your needs?

We’ve covered just about everything there is to know about stroker engines and whether they’re likely to be the right choice for your needs. If you’re not entirely sure whether a stroker is the route you’d like to go down, there are still several alternative options available:

- Increase the number of cylinders

- Increase the bore size of the existing cylinders

- Forced induction

- Destroking

- Engine swap

Stroking may not sound like the simplest method, but when you consider that increasing the number of cylinders will require an entirely new block, it’s often not worth the money, time or effort when you can just increase the displacement with a stroker.

So why shouldn’t you just increase the bore size? Well, this is the most common way of increasing engine displacement, however, due to limitations with how much the bores can be increased, you’re unlikely to see the same benefits from your stock block that you would if you opted for the stroker route.

Forced induction can be extremely beneficial, but often requires time and huge costs, and the chances are you’ll want to upgrade your internal components anyway to deal with the new-found power gains.

As for an engine swap, it may well be a choice worth considering if there is a convenient alternative for reasonable money, but generally, the chances are that stroking would once again win this argument.

There’s no doubt that fitting a stroker kit isn’t the easiest of tasks, especially for those without a substantial amount of knowledge and with the right tools hanging around. Disassembly, correct fitting and re-assembly can be extremely challenging and risky work.

With that being said, if you dare take it on yourself, or even if you pay someone to do it for you, we genuinely believe that stroker kits still remain one of the most cost-effective and convenient ways to achieve increased displacement.

Not only will you be delighted with the power gains, but you’ll also be able to retain your stock engine and provided you keep the other engine bay upgrades discreet, it’s the perfect opportunity to create a street-sleeper!

You’d be forgiven for thinking that stroker engines are mainly for muscle cars. With the drifting game continuously evolving, more and more drift cars are going down the stroker route. Check out this video of Kazuya Taguchi’s 1,100hp 4.1L stroked GTR laying tires at Hoonigan for some inspiration!

Additional stroker-related Content

Most of the incredible builds out there are fitted with strokers, so there’s certainly no shortage of media content! We’ve chosen some of our favorite YouTube picks here:

Something a little different, an SR22 AE86 throwing it down sideways in Europe!

Here’s another interesting video showing a full 700hp LS3 build. If you’re interested in learning more, you’ll love this.

Take a look at Dan Burkett’s 3.4L 2JZ Formula Drift stroker build:

We briefly discussed compression ratio, which is important when it comes to stroking. This great guide breaks it down if you’re keen to learn more:

Photography credits

Drifted would like to extend thanks to the following sources for use of their images:

- Animagraffs

- Wrangler TJ Forum

- Enjuku Racing

- Deft Motion

- Truck Trend

- JE Pistons